RTL to GDS-II flow Archives - Semiconductor Engineering

Abstract

The featured archive extensively covers the complete semiconductor physical design pipeline, detailing the critical conversion process from Register-Transfer Level (RTL) descriptions to the final manufacturing data format, GDS-II. It explores the methodologies and sophisticated Electronic Design Automation (EDA) tools required for synthesis, optimization, timing closure, and verification in modern deep submicron processes. This technical focus is essential for ensuring successful silicon tape-outs and optimizing power, performance, and area (PPA) across various hardware projects.

Report

RTL to GDS-II Flow Analysis

The "RTL to GDS-II flow Archives" likely contains discussions vital for anyone moving a digital hardware design from concept to manufacturable silicon. This entire process defines VLSI implementation.

Key Highlights

- End-to-End Design Coverage: The primary focus is the full physical implementation flow, starting with synthesized logic and culminating in the mask data required for fabrication.

- PPA Optimization: A key theme is the iterative optimization process necessary to meet demanding power, performance, and area (PPA) targets crucial for competitive silicon products.

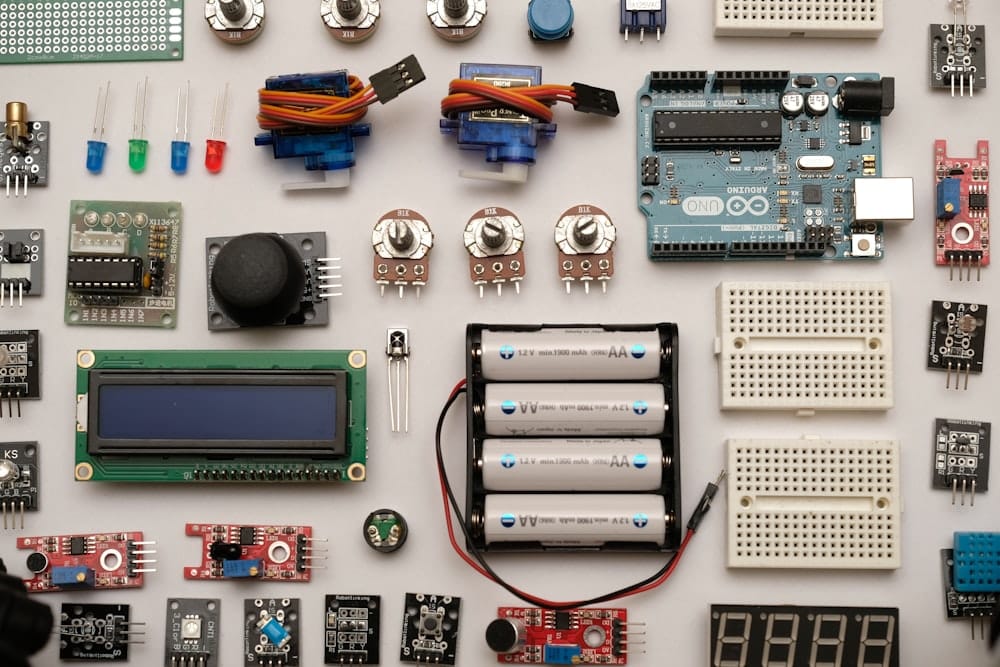

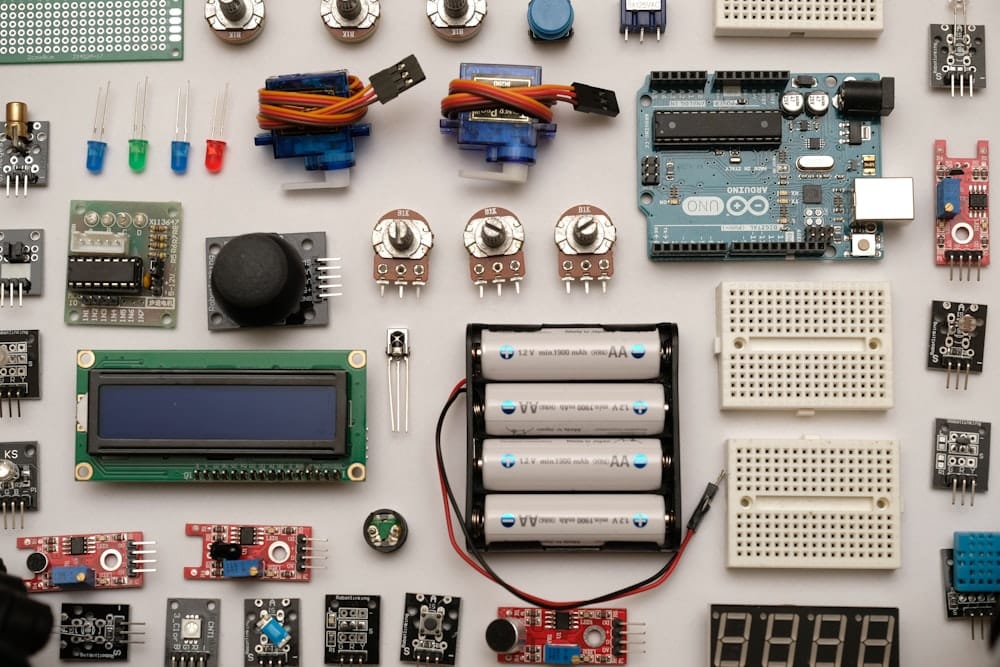

- Tooling Emphasis: The flow relies heavily on advanced commercial or specialized open-source Electronic Design Automation (EDA) tools for sequential steps like synthesis, placement, routing, and clock tree synthesis.

- Verification Criticality: Discussions emphasize the crucial final verification steps (Design Rule Check/DRC, Layout Versus Schematic/LVS) needed to guarantee manufacturability and functional correctness.

Technical Details

- Input Stage: Designs typically start with RTL (Verilog/VHDL), constrained by SDC (Synopsys Design Constraints) files, and target specific technology libraries (characterized timing and power models).

- Core Flow Steps:

- Logic Synthesis: Converting RTL into gate-level netlists targeting a specific library.

- Floorplanning & Power Grid: Defining the die area and distributing global power.

- Placement & Clock Tree Synthesis (CTS): Positioning standard cells and building a balanced clock distribution network to meet setup/hold timing requirements.

- Routing: Connecting nets based on timing and design rules.

- Static Timing Analysis (STA): Rigorous analysis throughout the flow to ensure frequency goals are met.

- Output Format: The final verified layout data is generated as a GDS-II stream file, which contains all geometric information for mask generation.

Implications

- RISC-V Ecosystem Maturity: Deep dives into the RTL-to-GDSII flow signal that the RISC-V ecosystem is moving past conceptual or FPGA-only implementations towards full commercial ASIC readiness, requiring professional-grade physical design expertise.

- Accelerated Custom Silicon: Understanding and streamlining this flow is essential for companies looking to leverage the freedom of RISC-V to develop customized, optimized silicon solutions (e.g., highly specialized embedded processors or AI accelerators).

- Addressing Advanced Node Challenges: As feature sizes shrink (e.g., 7nm, 5nm), physical effects (lithography constraints, electromigration, variability) become dominant. Discussions on this flow help practitioners adopt necessary techniques (e.g., DFM – Design for Manufacturing) to ensure high yield.

- Open Source Hardware Enablement: Transparency regarding successful implementation flows can help emerging open-source hardware projects (sometimes utilizing open-source EDA tools for older nodes) benchmark their methodologies against established industry practices.

Technical Deep Dive Available

This public summary covers the essentials. The Full Report contains exclusive architectural diagrams, performance audits, and deep-dive technical analysis reserved for our members.