Chip Industry Technical Paper Roundup: June 9 - Semiconductor Engineering

Abstract

The Chip Industry Technical Paper Roundup for June 9 compiles recent research breakthroughs across various facets of semiconductor technology. The featured papers generally focus on overcoming scaling limitations, implementing advanced 2.5D/3D packaging techniques, and refining design methodologies for next-generation computing. These innovations are critical for driving performance and efficiency necessary to meet the demanding requirements of AI, HPC, and specialized hardware architectures.

Report

Chip Industry Technical Paper Roundup: June 9 Analysis

This roundup summarizes recent advancements detailed in technical papers across the semiconductor ecosystem.

Key Highlights

- Advanced Scaling Challenges: Several papers likely address the complex physics and manufacturing hurdles associated with migrating to sub-3nm process nodes, including managing variations and enabling Gate-All-Around (GAA) or CFET structures.

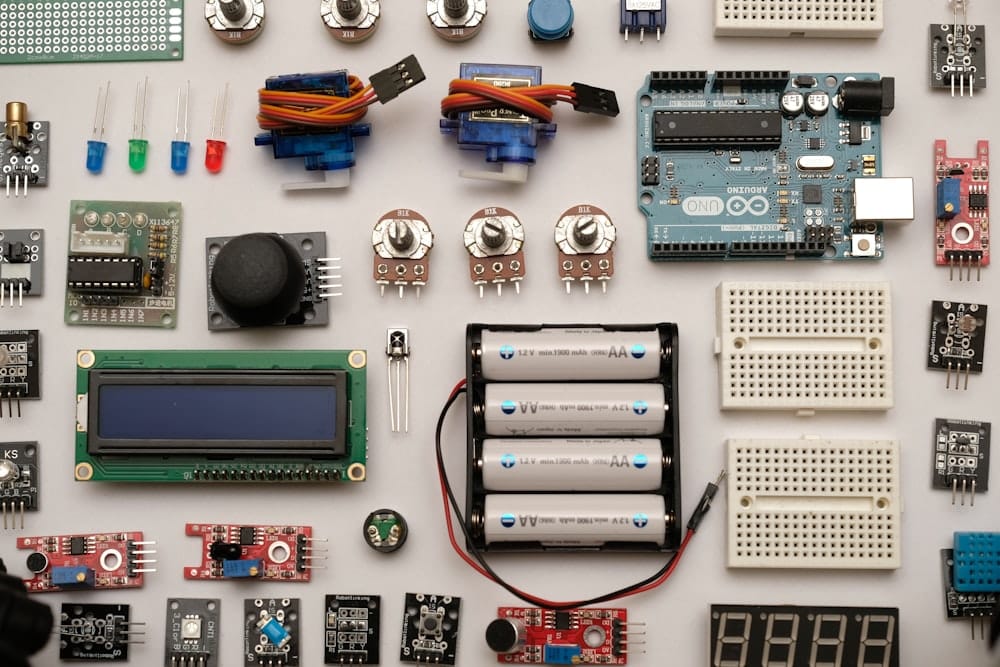

- Heterogeneous Integration: A significant portion of the research focuses on refining chiplet architectures, including improved die-to-die interfaces and advancements in complex 2.5D and 3D stacking techniques (e.g., hybrid bonding).

- Design and Verification: Papers often highlight improvements in Electronic Design Automation (EDA) tools, focusing on enhanced verification methods, power integrity analysis, and faster simulation cycles for massive chip designs.

- AI and Specialization: Research supporting hardware accelerators for AI and Machine Learning, exploring specialized memory solutions and domain-specific architectures, is typically a key theme.

Technical Details

- Packaging Technologies: Technical specifications likely detail improvements in interposer materials, micro-bump pitch reduction, and thermal management strategies for highly integrated multi-chip modules (MCMs).

- Process Innovations: Methods for reducing defects and improving yield for extreme ultraviolet (EUV) lithography or high-NA EUV may be described, alongside materials science innovations for low-resistance interconnects.

- Security and Reliability: Specific architectural details concerning hardware security features, such as cryptographic acceleration units or trusted execution environments (TEEs), aimed at improving chip resilience.

Implications

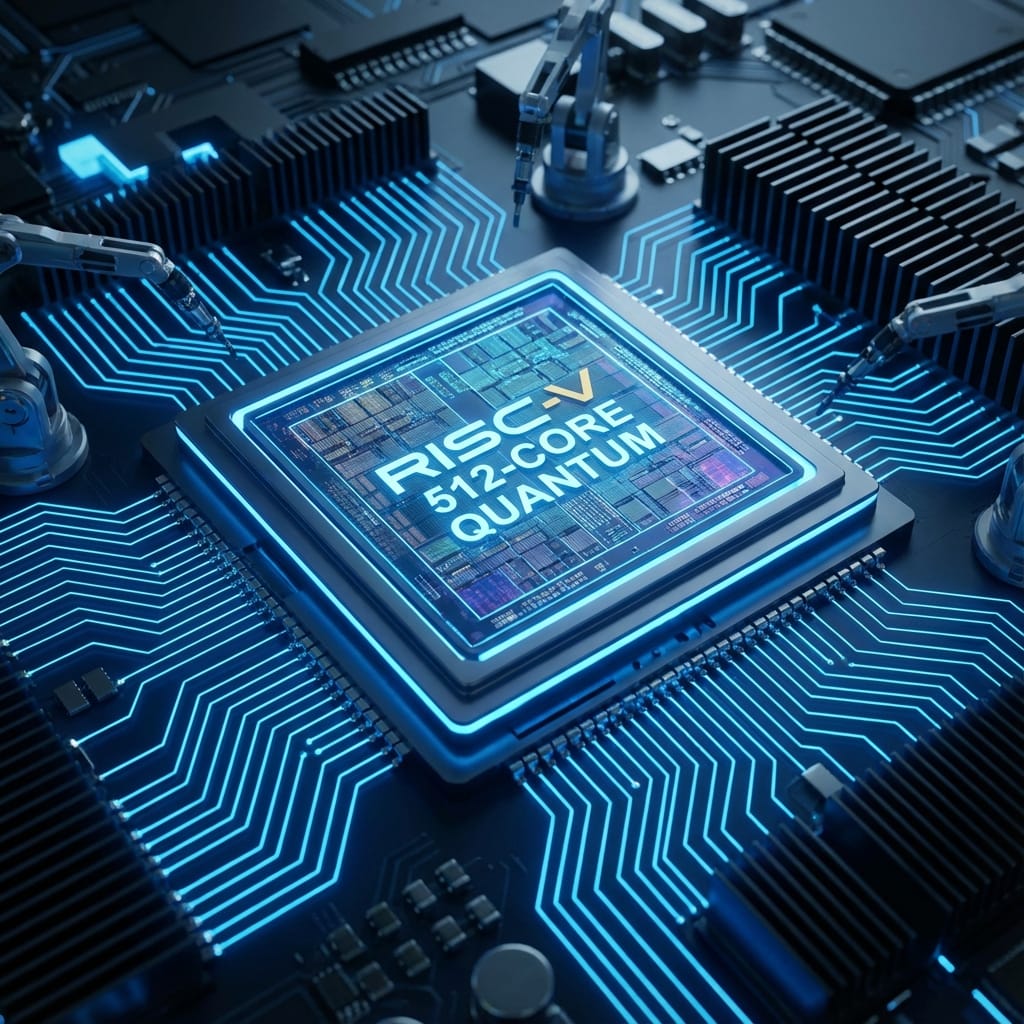

- RISC-V Ecosystem Boost: The continued industry pivot toward chiplets and 3D integration strongly validates the modular and customizability benefits of the RISC-V ISA, allowing easier integration of vendor-agnostic IP blocks.

- Accelerated Adoption: Advancements in EDA tools and verification methodologies summarized in the papers directly reduce the development cost and time for complex RISC-V implementations, encouraging faster commercial adoption.

- Performance Optimization: Research concerning advanced process nodes and power efficiency dictates how future RISC-V core designs must be optimized to leverage cutting-edge manufacturing capabilities, ensuring RISC-V remains competitive against legacy ISAs in high-performance computing markets.

Technical Deep Dive Available

This public summary covers the essentials. The Full Report contains exclusive architectural diagrams, performance audits, and deep-dive technical analysis reserved for our members.